The textile industry is 0.3% circular, according to the ‘Circularity Gap Report Textiles’

The sector consumes 3.25 billion tonnes of resources annually, of which 99% are virgin materials, and 30% of the clothes produced go unsold. These figures come from the report by Circle Economy and the H&M Foundation, which points out that adopting the principles of a circular economy could reduce the environmental footprint of the textile sector by 50%.

The amount of recycled materials used by the global textile industry is just 0.3%, primarily from plastic bottles, and textile-to-textile recycling is almost non-existent. This industry, which includes clothing, footwear, and home textiles, consumes 3.25 billion tonnes of resources annually, 99% of which are virgin materials. Petroleum-based synthetic fibres, such as polyester, account for 63% of the materials used. The primary problem of the textile industry is the overproduction of cheap, low-quality garments, predominantly made from synthetic fibres. Up to 24 collections are launched annually, and 30% of the clothing produced never gets sold. These are the main findings of the Circularity Gap Report Textiles, published by Circle Economy and the H&M Foundation.

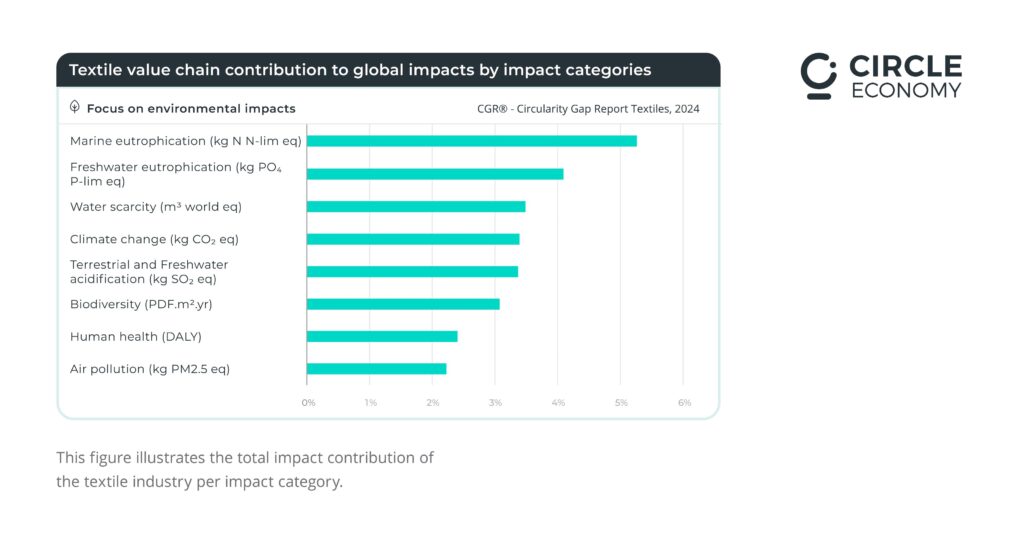

The textile industry is highly resource-intensive, relying on natural fibres derived from agriculture and synthetic fibres derived from petroleum. Producing these fibres requires significant amounts of water, land, and energy. According to the report, the textile sector contributes approximately 3.5% of global greenhouse gas (GHG) emissions, 5% to nutrient overloads that disrupt aquatic ecosystems, and 3.5% to water scarcity.

Two key players in environmental impacts

China and the United States play significant roles in these environmental impacts. China is the world’s largest textile producer, using 40% of all materials globally, while the United States is the largest consumer. In Europe, the average citizen consumes 26 kg of textiles and generates 12 kg of textile waste annually.

Textile production employs 140 million people, nearly half of whom lack formal contracts; this figure rises to almost 90% in developing countries. Overall, these workers often face extremely precarious conditions.

Can the textile industry become more circular?

The textile industry faces challenges such as the degradation of fibres during recycling and dilemmas like mixed fibres being more durable but less recyclable than mono-materials. According to the report, “it is better to focus on reducing material consumption and the associated environmental impacts.” Adopting circular economy principles could cut the textile sector’s environmental footprint by 50%.

Adopting circular economy principles could cut the textile sector’s environmental footprint by 50%.

Recommendations from the report:

- – Increased use of natural, local, and recycled fibres: Synthetic fibres primarily come from fossil fuels, contributing to climate change. Promoting natural fibres such as cotton, linen, silk, or wool could reduce emissions, although they may also impact soil and water. Improved textile recycling could help here; currently, recycled cotton accounts for just 1% of the plant-based fibre market.

- – More durable garments: Although synthetic fibres have a bad reputation, well-designed synthetic garments can be more durable.

- – Sustainable production of natural fibres: Transitioning to more sustainable agricultural practices is key to reducing environmental impacts associated with high land, water, and energy use. For example, organic cotton can cut emissions by up to 46%, while hemp requires 50% less water and fewer pesticides than cotton.

- – Shift from fast fashion to slow fashion: Textile and footwear consumption is projected to increase by 63% by 2030, a trend that could be reversed by adopting slow fashion—fewer collections annually, with an emphasis on reuse, repair, donations, and do-it-yourself practices.

- – More circular manufacturing: Traditional textile manufacturing often results in material waste due to cutting errors, pattern layout mistakes, and human error. Technologies like computerised and laser cutting systems, as well as computer-aided design, can reduce textile waste by improving material efficiency.

- – Change in supply chain dynamics: Shifting some textile production from Asia to major consumption regions like North America and Europe could reduce emissions due to stricter environmental regulations and shorter transportation distances. Brands could also prioritise transparent supply chains, sustainable practices, and fair labour standards.

Where does textile waste go?

Sixty-one per cent of textile waste ends up in landfills or is incinerated. Synthetic fibres rarely decompose and release harmful chemicals and greenhouse gases. Incineration, an increasingly popular method for generating energy from textile waste, emits greenhouse gases and destroys valuable materials.

Approximately 8% of discarded textiles are reused or exported. Over the past 30 years, the second-hand clothing trade has grown sevenfold. While these practices create jobs, they are often unregulated and precarious, as noted in the report.